Flux Chamber

Sampling of gazeous emissions on area source

Unlike a point source whose emissions are concentrated at a single point (e.g: stack), an area source is in fact a source whose entire surface emits odors or gaseous compounds in the atmosphere. These sources are often made of solid piles or liquid surfaces. These emissions from such area sources must be collected using a specialized equipment, called a flux chamber.

The Onose-8® flux chamber consists of a semi-sphere directly installed on the area source in order to collect the gaseous emissions escaping from the surface. A constant flow of inert gas is added inside the flux chamber in order to generate odours or gaseous contaminants by the movement of air inside the flux chamber. The use of the flux chamber allows to sample gaseous emissions from an area source without sampling or disturbing the emitting surface. It thus consists of a non-destructive gaseous sampling method.

Applications

The Onose-8® flux chamber can be used, without limitation, in the following cases :

- Windrow composting;

- Wastewater treatment plant;

- Retention basins;

- Field spreading simulation of organic residual materials, according existing standards;

- Landfill sites;

- Contaminated soil;

The Onose-8® flux chamber offers the following advantages:

- Manufactured entirely in stainless steel;

- Easy to clean;

- Avoiding cross-contamination;

- Equipped with 4 vents on the sides, complying with the requirements of the US EPA;

- Robust and durable

Download the brochure

Operation Flux Chamber

Made entirely of stainless steel, the Onose-8® flux chamber, designed and marketed by Consumaj Inc., meets the design criteria of the US EPA. A floating chamber can also be installed around the flux chamber to facilitate the sampling procedure of gaseous emissions of a liquid surface. Emission sampling lines and inert gas lines of various lengths can also be mounted on the instrument. A temperature sensor port is also available on all models proposed by Consumaj Inc.

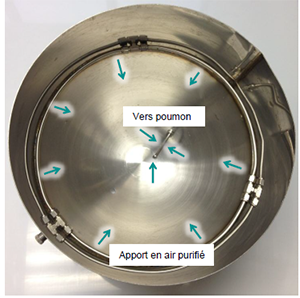

The flux Chamber retrieves the gaseous emissions from solid or liquid surfaces emitting gaseous contaminants and odors. To be able to extract odours and contaminants from a surface source, it is needed to produce a turbulence with airflow inside the flow Chamber. This turbulence on the surface of the source will retrieve odours or contaminants emitted by the surface this source. To produce that turbulent airflow, the flux chamber must be connected to a supply of purified air by the O-ring (item C). This purified air will be distributed inside of the sampling chamber (point A) via the distribution air supply line (item F). This distribution line is responsible to create a turbulent airflow over the surface of the source to be sampled. This turbulence on the surface of the source will retrieve odours or contaminants emitted by the surface this source.

Turbulent air containing contaminants or odors emitted from the surface source are subsequently sucked by the sampling rod (point E) located inside the sampling chamber (point A).

This air collected by the sampling Rod will be subsequently directed by vacuum to the O-ring of the vacuum chamber (point B) before joining the Onose-8® sampling bag located in the Onose – 8® vacuum chamber.

A 0.25 inch (6 mm) diameter Teflon tube must be installed between the O-ring of the vacuum chamber (point B) located on the sampling chamber (point A) and Onose – 8 ® vacuum chamber.

To perform an adequate sampling, the flow of fresh air supply which is distributed inside the flux Chamber must be slightly higher than the sampling flow rate. The excess air inside the flux chamber will be naturally expelled outside the flux chamber through the overflow hole (point D). The overflow hole also allows to insert a temperature probe.

The following diagrams indicate the direction of flow of the gases inside the flux Chamber.

For any information pertaining to the purchase of the olfactometre, we will me more than happy to talk to you or answer your email Please use the following address: info@onose.ca

Features: Flux Chamber

| Manufacturer | Consumaj inc. |

| Instrument | ONOSE-8® Flux Chamber |

| Product Number |

|

| Diameter | |

| Height |

|

| Volume | 30 liters (1 ft 3) (CMJ-VC-200-900) 60 litres (2 ft 3) (CMJ-VC-300-900) |

| Sampling volume | 20 liters (0.7 ft 3) (CMJ-VC-200-900) 50 liters (1,8 ft 3) (CMJ-VC-300-900) |

| Sampling length | 1 minute à 24 hours |

| Materials | Teflon, Nalophan, stainless steel |

Components flux chamber

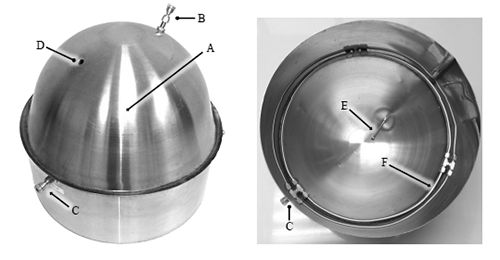

The following figure illustrates in detail the components of the flux Chamber Onose – 8 ®. The flux Chamber is composed of the following parts:

- A Sampling chamber;

- B O-ring towards vacuum chamber;

- C O-ring for the entry of purified air;

- D Overflow hole;

- E Sampling rod (inside the sampling chamber);

- F Distribution line for purified air (inside the sampling chamber);

- G Buoyancy chamber.