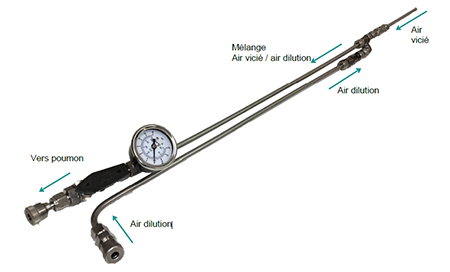

Sampling probe with static dilution

Gaseous contaminants and odours from point source emissions are often concentrated or have a high moisture content, often making olfactometric and analytical analysis difficult to achieve. Predilution of gaseous emissions directly at the source using a pure and dry air supply is often necessary to avoid inconvenience associated with moisture condensation or strong odour concentration of the gaseous emissions collected. The Onose-8® sampling probe, designed and marketed by Consumaj Inc., allows the dilution of the gaseous samples directly inside the emission source during the sampling procedure. Thus, the dilution at the source has for advantage to reduce the contaminant and odour concentration and also to avoid moisture condensation before the sample reaches the sampling bag.

The predilution sampling probe allows gas sampling from a point source of gaseous effluents. Onose-8® sampling probe can be used for:

Two types of probes are available in the Onose-8® line of products:

- For the removal of odours or gaseous contaminants;

- For sources with a temperature of release of more than 500 ° C and relative humidity of 100%.

This probe has been designed to provide various dilutions rate specific as well as ruggedness and ease of use. Onose – 8 ® sampling probe has been designed according to the criteria of the EN 13725 standard. The sampling probe was designed using parts and Swagelok connectors. This allows mounting and easy disassembly during maintenance, as well as a minimum of leakage between the parts joints.

Applications

The Onose-8® static predilution sampling probe has two ports. The first port is inserted into the point source emission in order to collect the gaseous emissions. The second port is connected to a pure, dry air supply used to dilute emissions from the source. The mixture of pure air and gaseous emission occurs inside the point source in a specially designed mixing chamber. This dilution minimizes the risk of moisture condensation in the sampling bag since the temperature at which the dilution between the pure air and the gaseous emission occurs is the same as the temperature of the point source. The mixture of gaseous emissions and pure air is then collected with the Onose-8® vacuum chamber inside an Onose-8® sampling bag.

Download the brochure

Operation of the sampling probe

The sampling probe operates through negative pressure (vacuum) induced within the probe. This negative pressure allows the sensor to capture the stale air to collect and mix it with the dilution air (clean air). This negative pressure is produced by Onose-8® vacuum chamber when it is connected to the sampling probe via vacuum chamber o-ring (item H in the previous figure). A tube with an outside diameter of 0.25 inch (6 mm) can be used to connect the sampling probe to the vacuum chamber.

To collect a stream of exhaust air, the Onose-8® pre dilution sampling probe must be inserted into the point source so that the end of sampling of the probe (point A), the hole in the exhaust air (B), the dilution Chamber (C) as well as the opening of the dilution air (Point E) are inserted fully inside the source. This allows the exhaust and dilution air (clean air) to mix in the dilution Chamber at the same temperature as the airflow of the point source.

The vacuum created inside the sampling probe permits to collect gaseous effluent through the end of sampling probe (point A). The sampling of gaseous effluent flow rate is determined by the hole in the exhaust air (point B). Different ports may be used with the sampling probe Onose – 8 ®.

Each of these holes has a different diameter and thus allows to obtain different sampling and dilution rates.

La chambre de dilution de la sonde d’échantillonnage Onose-8®, permet de mélanger l’apport d’air vicié provenant de la source ponctuelle et l’apport d’air frais et inodore nécessaire à la dilution.

Tout comme l’air vicié, l’air frais servant à la dilution est introduit à l’intérieur de la sonde d’échantillonnage par la pression négative engendrée par le poumon sous vide Onose-8. Un sac d’échantillonnage Onose-8® rempli d’air frais (ou d’azote) est connecté au joint torique d’air de dilution de la sonde à l’aide d’une valve à raccordement rapide (non inclus avec la sonde d’échantillonnage). Le débit d’air frais entrant dans la sonde d’échantillonnage est contrôlé par l’orifice de l’air de dilution, permettant d’obtenir un taux de dilution air vicié/air frais précis.

L’air frais de dilution et l’air vicié entrent donc dans la sonde d’échantillonnage par leur orifice respectif avant de se rejoindre dans la chambre de dilution afin d’y être mélangés à un taux de dilution connu. La précision du taux de dilution est assurée par le certificat d’étalonnage de la sonde de prédilution Onose-8® et par le manomètre de la sonde. Ce manomètre permet de connaitre la pression négative lors de l’échantillonnage.

Connaitre la pression négative à l’intérieur de la sonde est important, car elle permet de déterminer avec précision le taux de dilution, tel qu’indiqué sur le certificat d’étalonnage de la sonde.

Une fois la dilution air vicié/air frais effectuée selon un taux de dilution prédéterminé, le mélange est ensuite dirigé, grâce au vide créé par le poumon sous vide, vers le manomètre et la valve. Le mélange air vicié/air frais est ensuite éjecté à l’extérieur de la sonde d’échantillonnage par le joint torique du poumon sous vide. Le mélange est ensuite acheminé à l’aide d’un tube vers le sac d’échantillonnage situé dans le poumon sous vide.

Once inside the sampling probe, the odorous gas effluent is directed to the dilution Chamber, where the smell will be mixed with the dilution air supply (clean air or nitrogen) to produce a diluted sample.

For any information pertaining to the purchase of the olfactometre, we will me more than happy to talk to you or answer your email Please use the following address: info@onose.ca

Features: Sampling Probes

| Manufacturer | Consumaj inc. | |

| Instrument | Onose-8® Sampling Probe | |

| Product Number |

|

|

| Lenght* |

|

|

| Material |

Stainless steel only Stainless steel and Teflon® |

|

| Dilution Ratio | 1:5 à 1:60 |

|

| Maximum Temperature | More than 500oC Up to 120oC |

|

| * Special orders accepted |

Components for the sampling probe

The sampling rod with a pre-dilution function is equipped with a valve, a nanometer and a connection for a quick hook up to the vacuum sampler. The pre-dilution is achieved inside the source, and then directly sucked into the sampling bas inside the vacuum sampler. Compatible with the Consumaj sampling bags and vacuum sampler, the sampling rod is made of stainless steel. Accordingly, it can sample emissions at a maximum temperature of 500 °C and 100 % relative humidity. The static pre-dilution function can provide dilutions varying from 1 to 100 parts air to 1 part emission.

The mixture of fresh air and emission from the source is done within the emission source and is then transported to the sampling bag. Onose – 8 ® Sampling bags and vacuum chamber marketed by Consumaj Inc. are all compatible with static pre-dilution sampling probes.

Regardless of the type of sampling probe used, the probe dilution ratios can be changed as needed. Dilution ratios offered with the Onose-8® static predilution sampling probes vary between 1:2 and 1:80.

- The sampling probe completely made of stainless steel can withstand temperatures above 500° C.

- Pre-dilution probe made of Teflon and stainless steel is easier to handle, is more compact and can withstand temperatures up to 120° C.