Vacuum Chamber

The Onose-8® vacuum chamber is an instrument used for the sampling of odours and gaseous emissions The Onose-8® vacuum chamber consists of a solid cylindrical structure that allows sampling bags to be filled using the negative pressure provided by a vacuum pump. This vacuum chamber can fill sampling bags varying from 2 L to 60 L in volume.

Applications

Made of durable material, the Onose-8® vacuum chamber can withstand significant negative pressures. This tool can also be used in addition with other Onose-8® products, such as the wind tunnel, the flux chamber, or the static predilution sampling probe. This instrument can also be used with all the Onose-8® sampling bags of all different dimensions and volumes offered by Consumaj Inc. in order to collect gas samples.

Download the brochure

Operation Vacuum Chamber

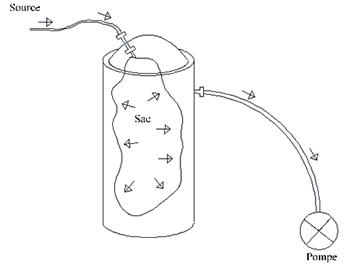

The Onose-8® vacuum chamber is composed of two main parts: the lid and the vacuum chamber. An Onose-8® sampling bag is inserted inside the vacuum chamber by connecting it to the lid through a double shut off quick disconnect valve. Once the sampling bag is installed inside the vacuum chamber and connected to the lid, it is only necessary to install the lid on top of the vacuum chamber and to induce a negative pressure inside the chamber with a vaccum pump. The lid, designed to completely seal the vacuum chamber, is transparent. This characteristic allows the operator to observe the sampling bag inside the Onose- 8® vaccum chamber during the filling procedure. Once a vacuum is induced inside the vacuum chamber, the gaseous sample is automatically accumulated in the sampling bag.

Benefits

The main advantage of the Onose-8® vacuum chamber, compared to other sampling methods, is that it guarantees the integrity of the sample. In fact, the only materials which come into contact with the gas sample are made of stainless steel, Teflon® and Nalophan®. Thus, there is no need to pump the sample through a vacuum pump in order to fill the sampling bag. This is the pressure gradient between the ambient air and the vacuum chamber that allows the sampling bag to be filled. The risk of crosscontamination between samples is reduced when using the Onose-8® vacuum chamber.

Furthermore, it is also possible with the Onose-8® vacuum chamber to adjust the sampling duration necessary to fill the sampling bag. The sampling duration can be adjusted from 1 minute to 24 hours.

The principle of operation of the vacuum chamber is based on the balancing of the pressure between the inside and the outside of the chamber. So as to accumulate the gaseous effluent to be taken inside the vacuum chamber, a vacuum must be induced within the sampling chamber (point A). This vacuum is produced using a vacuum pump. This pump must be connected to the chamber via the vacuum pump connector (point C), located on the side of the sampling chamber (Point A) of the vacuum chamber. A valve (point D) located on the vacuum pump connector (point C) allows to adjust the vacuum of the sampling chamber. If the valve of the fitting is opened, the vacuum inside the lung increases. If the valve is subsequently closed, the vacuum stabilizes; or decreases if outside air enters the chamber through the fittings of the sampling equipment (point F) and the fitting of the sampling bag (item E) located on the lid (item B) of the vacuum chamber.

For any information pertaining to the purchase of the olfactometre, we will me more than happy to talk to you or answer your email Please use the following address: info@onose.ca

In order to store gaseous effluent collected inside the sampling bag it must be connected to the sampling equipment with the sampling equipment connector (item F) located on the lid (item B) of the vacuum chamber. Thus, when a vacuum is induced inside the chamber, the balance of pressures will ensure that the gaseous effluent will naturally flow though the sampling equipment into the sampling bag.

The sampling procedure for a source of gaseous effluent using vacuum chamber is as follows:

- Wear the individual protections required for a safe work according to conditions;

- Make sure you have safe access to the sampling source to be sampled;

- Make sure you have at hand all the equipment and tools needed for sampling;

- Install an Onose-8® sampling bag inside vacuum chamber and connect the bag to the cover of the chamber (item B) using the sampling bag quick-connect fitting (item E);

- Install the lid (item B) on the sampling Chamber (point A) to seal the vacuum chamber;

- Connect the vacuum pump and the vacuum pump connector valve (item D) to the Onose-8® vacuum chamber;

- Close the valve of the vacuum pump connector (point D);

- Connect the gaseous effluent sampling equipment to sampling equipment connector (item F) located on the lid (point B) Onose-8® vacuum chamber by using a line of Teflon ® with an outside diameter of 0.25 inch (6 mm);

- Start the vacuum pump;

- Open the valve of the vacuum pump connector (point D);

- Open and close the valve of the vacuum pump connection (point D) in order to obtain the desired vacuum within the chamber.

The following diagram shows the operating principle of the ONOSE – 8 ® vacuum chamber.

For any information pertaining to the purchase of the olfactometre, we will me more than happy to talk to you or answer your email Please use the following address: info@onose.ca

Features: Vacuum Chamber

| Manufacturer | Consumaj inc. |

| Instrument | Poumon sous vide ONOSE-8® |

| Product Number |

|

| Diameter | |

| height |

|

| Volume | 30 liters (1 ft 3) (CMJ-VC-200-900) 60 liters (2 ft 3) (CMJ-VC-300-900) |

| Sampling Capacity | 20 liters (0.7 ft 3) (CMJ-VC-200-900) 50 liters (1,8 ft 3) (CMJ-VC-300-900) |

| Sampling Duration | 1 minute à 24 hours |

| Wetted Material | Téflon®, Nalophan®, stainless steel |

Components vacuum chamber

The following figure illustrates in detail the components of the Onose – 8 ® vacuum chamber. Vacuum chamber consists of the following parts:

- Sampling chamber;

- Lid;

- Vacuum pump connector;

- connection valve of the vacuum pump;

- Smpling bag connector (inside the vacuum chamber);

- Sampling equipment connector;

- Handles.